SOFO - SAMPLE CUTTER

This interview is with Sofo, a sample cutter I worked with at Mary Katrantzou. Sofo has been a cutter for 40 years, and much of his family also worked in the fashion industry in the seventies and eighties. He started off working in factories where they were fulfilling production orders. As the industry has changed over time, and production has moved abroad, he now works on the sampling side, in house working for London Fashion Week designers. We spoke about the tools of the trade, his advice on cutting accurately (hint – it is all in the preparation), and that he started off by making the tea in his first job.

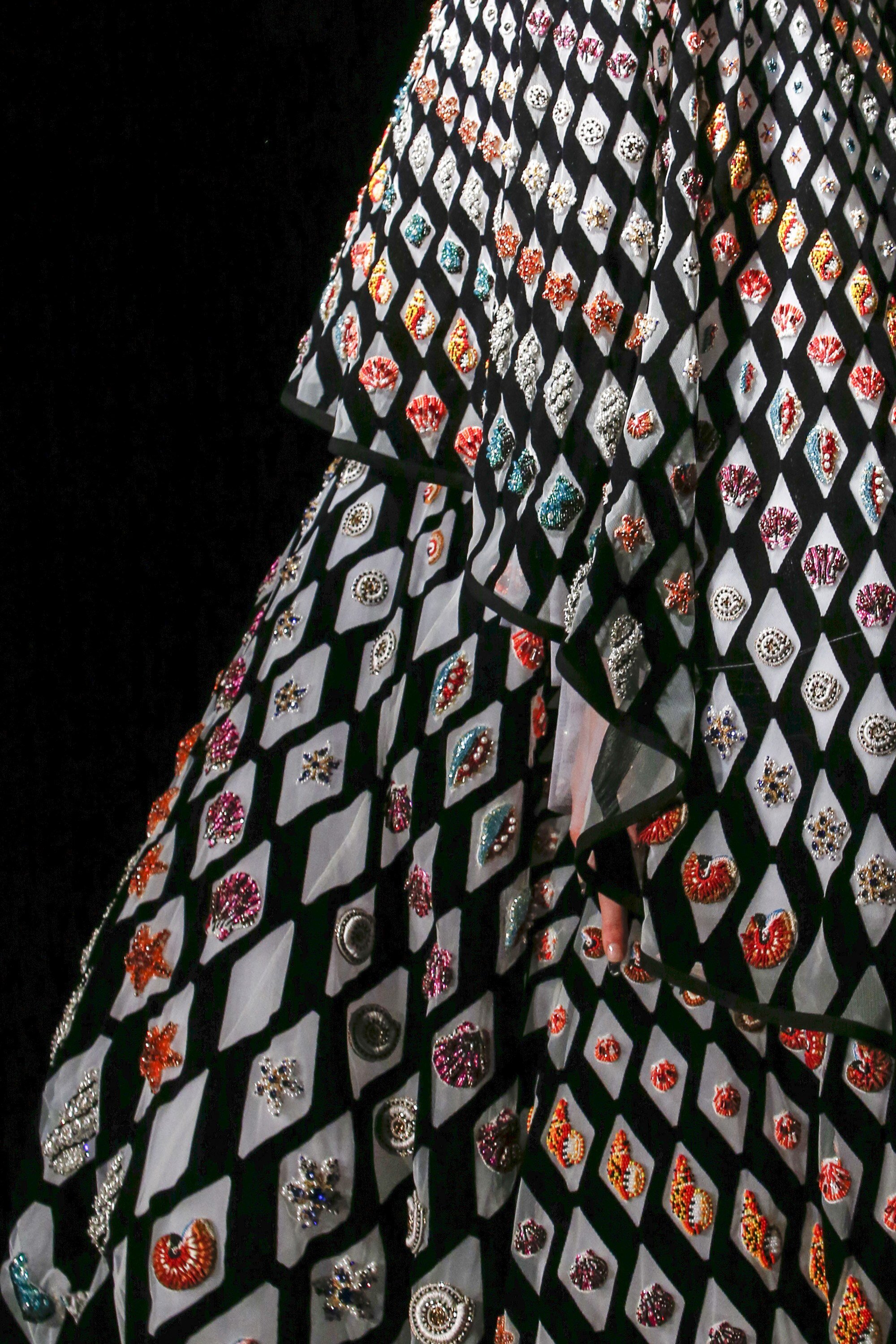

Sofo is a wizard when it comes to matching seams when cutting. Often when fabric is printed and embroidered, the fabric will shrink or move and not quite fit the pattern any more, and that’s where the skill of a great cutter will shine, they will somehow make it fit. The mark of a good cutter is that you don’t actually notice how good they are. It’s only when something has been cut badly that most people will notice that a seam doesn’t quite match up. Next time you’re out at the shops, take a look at printed or patterned garments, has it been cut well?

An example of Sofo’s cutting from Mary Katrantzou SS19 - spot the seam line!

Another example of Sofo’s cutting from Mary Katrantzou SS18 - see how the print is matched at the CB and on the side back bodice seams. This is the team work between a cutter and a seamstress.

What is a sample cutter?

Currently I am a sample cutter working in house at Mary Katrantzou, but I have also worked as a production cutter in factories. I start by cutting the toiles, and eventually we go to the final garments that are shown on the catwalk. We cut everything as a sample cutter, we cut one by one, it’s not like in industry or mass production in a factory, where they cut hundreds or thousands. Here I just cut one at a time. Working here at Mary's where there are a lot of engineered prints and patterns, a big part of my job is making sure that the prints will match up across the seams once they are sewn.

What is the job of a production cutter in the fashion industry?

First I would make a marker, which is a cutting plan in the actual scale. I would make them by hand, not on the computer. We would get the graded patterns in cardboard, in whatever sizes they wanted, and a document saying how many they want cut of each size. We measured the width of the fabric and mark that on the dot and cross paper first so we can see how wide the marker should be. Then we would lay the patterns out on the paper and make it as economical as possible. You would move the pieces around, trying to find how they would fit and tessellate best. Then you would draw around them, to make one long lay plan. In those days, that's how the factories made their profit, because every centimetre you can save, you're saving fabric to make more garments. So instead of a garment taking 1.5m of fabric, if you can cut it out in 1:45m, then you are saving five centimetres. So it's about four or five percent, but sometimes you can save more. Instead of a thousand garments you can make 1050 garment. Because you've saved this fabric, the fabric is essentially free for those final 50 garments, as it has already been costed in the first 1000 garments.

How and where did you learn your skill?

Basically through experience, when I first started, I was just making the tea. Then you go on to the next step, where you start cutting, firstly by hand, then cutting with the machine. Then I started making markers, I even made patterns and I started doing some grading. So over the years, you just try your hand at more and more. Basically you have to look, you have to observe and you have got to use your brain to learn. Obviously there were schools that were teaching skills for the fashion industry, like grading or how to make good patterns. We used to go at night to college. There were a lot of opportunities to learn, until they started doing the production abroad in other countries. Now the fashion industry in London is just for the designers, that's what’s left today. There's nothing left of mass production now in the UK.

What was the cutting machine that you used?

We used to know it as an 'Eastman machine' which is the company that is making papers now. It had an 8 inch or 11 inch vertical blade. You would lay several layers of fabric down on top of each other, and place your marker on top. Then you could pin all the layers in place to stop them moving, using very long pins with a head. Then you would guide the cutting machine around by hand, following the cut lines on the marker. You would wear a metal glove on the hand that wasn't holding the machine, in case that hand got too close to the blade. I also used machines that had round spinning blades, but that one was more dangerous.

Sometimes you would use a temporary adhesive to hold the marker on to the top layer of fabric, but it was expensive so nobody really used this method. To make the drill holes to mark where a dart ended, we would use an actual drill. We did the notches with a machine, you had to be really careful that the fabric doesn't tilt, otherwise you end up with a big notch at the top of the pile and a small notch at the bottom or vice versa. You had to be extra careful with everything. We would also have to apply the piece fusing to all the pieces. Bear in mind, if you were cutting a directional fabric like velvet, and you made a mistake on the marker and put one piece the wrong way up, you are playing with thousands of garments, and there might not be any more fabric left! [Just as an aside from me, this is why a grainline should only have one arrow head, pointing down to the feet of the wearer. If it has two, how do you know at a quick glance, which way up the piece goes?]

This is an Eastman cutting machine. Image from Eastman

How long have you been in the industry and where have you worked?

Over forty years. A very long time, since I left school, it was my first job. People say to me, you must be the only person who likes your job. When you do production cutting it can be a bit boring. But actually in my career I was doing the patterns, doing the grading, doing the cutting, I have done many different things, and that was breaking up the monotony of just laying up and cutting.

What other brands have you worked for as a sample cutter?

I've been a sample cutter for about 10 years, I've been at Mary Katrantzou for about 6 years. I started with an agency and they would send us to different jobs. Wherever you go, if they like you then they keep you there for a long time. So I've worked at Victoria Beckham, Vivienne Westwood, Peter Pilotto, Marks & Spencer.

How did you get your foot in the door in the fashion industry?

Back then, everyone was looking for good cutters and seamstresses. There were more jobs then, because all of the production was done in the UK in the seventies and eighties. Then Marks & Spencer started to produce in China, they were the first ones who moved production abroad. My mother was a seamstress and my brother was pressing, my brother in law was a driver in the industry, my sister was an overlocker.

“i’ve been in the fashion industry over forty years. A very long time, since I left school, it was my first job.”

So your whole family worked in the fashion industry?

Yes but not just my family, everybody was working in the industry. Like 80- 90% of the Greek community in London. It was 80% in the fashion industry and the other 20% were in the catering industry, but there was a very big demand for the fashion industry in those days.

What was the best thing you were taught when you were starting out?

It might be funny to some, and this wasn't when I was starting out, but more recently. Maybe 8 or 9 years ago, I learned how to use a roller cutter. I had never used one before! I was given one at Pilotto, to cut leather. They cut everything there with the roller cutter, it was much smoother, much easier. You need to change the blade to ensure that it is very sharp and wont snag the fabric or leave a thread uncut. Obviously there are still many times when I still use my scissors, but generally you can use it to cut anything, on curves, on straight lines. The only thing that you definitely don't use it for is notches, because you can’t control exactly how deep it will cut.

Do you have some tips for home sewers when they're cutting out their projects at home, do you have any advice?

The strongest advice is to snip and tear the fabric before they even start because then when they lay it out to cut anything, they can line up the selvage and cross grain at a right angles on dot and cross paper, or using the right angle of a table. If the fabric is not straight, especially chiffon, single georgette and slippery fabric, after you cut it you can lift it up and you can see where it is not straight. [An aside from Helen - I have seen seamstresses hand pieces back to cutters if they have not been cut straight and ask them to re-cut. This will pretty much always be because the fabric has not been laid straight in the first place. If a seamstress is sewing a pin hem and the fabric is wavy at the bottom, it will show when they have finished sewing, so in order for them to do their job properly, the piece must be cut properly to begin with.]

“A seamstress can un-stitch, and a pattern cutter can rub out a mistake on their pattern. But when you cut, you cut.”

What's your favourite tool to use at work and why?

Obviously you can't do my job without scissors, but having very good scissors is a must. A good pair of scissors should be pointed enough to control and cut your notches cleanly with the tip. But not too pointed that they are going to catch on the surface of a table, some scissors are just too pointy! Sometimes you get scissors that don't meet at the end properly, so you think you've done a good notch, which are very important for the seamstress, but when you look, there is nothing there, or it is very tiny.

Do you have a favourite garment or fabric to cut?

All fabrics react differently to other, but the thicker the better for me because you can lay it down straight. My least favourite is velvet. (Which is funny because in my interview with seamstresses Ligi & Estera, they said that their least favourite fabric to sew was also velvet!)

What is the most exciting project you’ve ever worked on?

The first one I cut out at Mary Katrantzou about six years ago. I think it was called Tia Maria.

What is the best part of your job?

Taking final fabrics into a proper final sample, ensuring that the print or pattern is matching. Not necessarily the engineered prints as that is mostly worked out for you by the print designer, but lets say a stripe or a plaid, where the cutter really has to decide the best way to match the design of the fabric to ensure the final garment looks good. This can be things like making sure the centre of the repeat of the print falls in the centre front of the garment, and ensuring the print matches horizontally around the body. Can I get it to match at the side seams and at the centre back too?

What advice would you give someone that would be hoping to become a sample cutter?

Dedication and common sense, they have to be really interested in it. You are teaching yourself, but you have to think all the time. You can't be distracted, because once you cut, especially if it's a final garment, you cannot un-cut. A seamstress can unstitch, and a pattern cutter can rub out a mistake on their pattern. But when you cut, you cut. The seamstress are relying on you to cut the right thing, so you have to concentrate to ensure you are doing a good job for them.